How to Fix some Common Mistakes of a Router Table

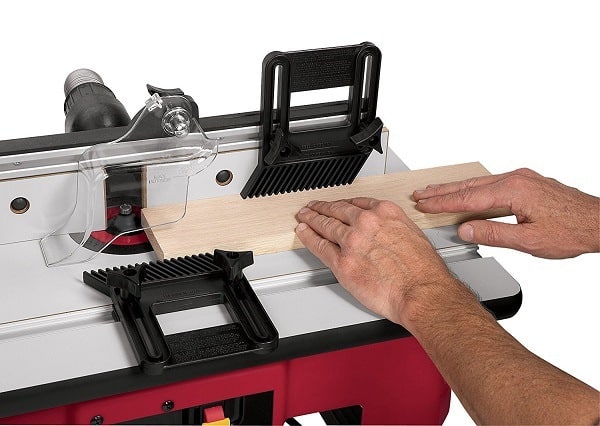

One of the key roles of the woodworker in his or her workshop is to keep the workshop tools in excellent working condition. The router table in particular is very important when handling any task in the workshop and it is quite easy to implement any technique using a wood router.

However, it becomes frustrating to accomplish even small tasks when the router table is not in good working condition. Instead of spending a lot of your money to pay a repairman to fix your table, consider fixing some of the problems on your own.

Some of the most common problems

Power Issues

In some instances you try to switch on your power tool and it fails to turn on. This is quite frustrating. If there is no response on your router table when you switch on the power switch then you have to check out a number of things.

First off, check whether the router table is plugged in or not since the power cord might have been pulled out accidentally while you were cleaning the workshop. Secondly, check the circuit breaker. If the problem is not on the fuse then you have to call the repairman.

Slipping Bit

There are instances when the router bit keeps slipping in the chuck when you are working on your project. When you evaluate the router bit, you realize that the bit stops while the chuck still turns. In this case you simply stop the machine and tighten up the chuck.

If this fails to solve the problem, check out whether the chuck key has been stripped or not. This may be the reason why the chuck does not tighten. If you are using an older router table you may have to replace the chuck since it no longer locks or its clamping mechanism is now worn out.

Bit Depth

Most woodworking projects require specific router bit heights and with the router table, the wood worker can set the bit depth using a gauge provided on the side of the table. However, after some time sawdust accumulate in the chuck and this pushes the bits higher. Therefore becomes a challenge to set the required bit height when working on the projects.

To solve this problem, you need to use some compressed air to eliminate the sawdust or the wood chips from time to time. As for the sawdust that has been compacted, you can use a screwdriver to break the sawdust loose then use the compressed it to blow it out.

Unstable or Inconsistent Bit Speed

Commonly referred to as stalling, inconsistent bit speed usually comes up due to worn out or loose belts. You need to first of all cut off power supply to the router table then open the router table’s housing and evaluate the belts. Check out for any abnormal wear or belts that have cracked for older machines.

If you fail to trace any problem with the belts, evaluate whether they are well connected to the drive wheels. You can then tighten or replace belts by following the instructions provided in the user manual from the manufacturer. If the problem persists then you have to contact a certified repairman.

Rigid Guide

The router table’s guides are just as important as the router. Without the guides, it would be impossible to make precise and accurate cuts in line with your required dimensions. Some of the common fault with the guides is that they tend to freeze into place whenever temperatures fluctuate from hot to cold, more so when you have not used the router table for a while.

To rectify this problem, you need to loosen the bolts using a pair of pliers. You should be careful not to break them while doing this. A lubricating fluid will be helpful in loosening the bolts. In case you use a lubricating fluid, ensure you check and confirm that the bolts are locked into place a few times when you will use the router table.

Additional Tips-Avoid these Mistakes when Buying a Router Table

Fixed Mindset Over a Particular Brand

Most woodworkers venture into the market with a specific brand in their mind. This is a major mistake and should be avoided. Just because certain brand is new or is being used by a friend does not mean it will suit you. To avoid this mistake consider the features of the brand you are evaluating. You can save money and enjoy excellent benefits by buying an unpopular brand that has what you are looking for.

Settling for Too Small

This is perhaps one of the most common mistakes the novice make when they first get their router table. It is always tempting to buy an inexpensive table but remember soon you will outgrow such a router table. You should instead invest wisely in a table that has industry standard parts that will enable you to use accessories such as fences, miter gauges, and many others. Buy a table you can grow with.

Failure to Plan for a Dust Collector

Most woodworkers do not think about a dust collector when getting their first router table and yet this feature is a needed later. You need a dust collection since the router table gets messed up when worked on. It will minimize your cleaning job.

Buying Everything

This is a common mistake that most woodworkers commit from time to time. If you are buying a router table for the first time then it is wise you work with one for a while before getting another. Avoid spending too much on every accessory and table you see and focus on one table with a few accessories at first. You can later on add in some other things.

A few final words

Your first router table may be costly and therefore it will take some time before you think of getting another one. Even if it is not your first router table, you do not want to keep buying a new one after a short time. You should therefore understand how to regularly service and fix some common faults with the router table.

Some of the common mistakes with a table are not as complex as you may think and you can save a lot of money by fixing them yourself. With the simple tips above you can easily fix some common problems associated with the router table.