What are the Best Materials to Use with a CNC Router?

You can achieve better finishing results using computer numerical control (CNC) routers on different materials. For better results, you can always familiarize yourself with various materials which you can work on with a CNC router. In this piece, you will learn a great deal about different materials that can give you excellent results with CNC routers. Ready?

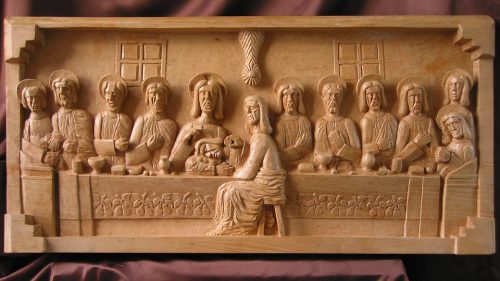

Wood

1) Softwood

Softwood includes plywood, chipboard among others. Mostly, softwood comes from Gymnosperm trees, for example, pines, spruce, larch, redwood and many more.

2) Hardwood

Hardwood materials are extracted from the Angiosperm trees such as Ash, Beech, Walnut, and Mahogany among others.

3) Superfood

Also known as medium density fiberboard (MDF) they are mainly used in the sign and the exhibit industries. The material is made through conversion of wood chips into fibers. The resin in liquid form is added to make a thick mat which is then pressed into boards by the help of heat and pressure.

The main reason for using MDF androxine kaufen alpha pharma in deutschland muscle for the graphics industry is due to the product’s uniformity property throughout even at the edges. The edges are usually smooth and appealing after using a CNC router on them. However, you will need to use paint on MDF as a finish to the final product.

For information about selecting a wood router… check out our full review guide.

Foam

1) Low-density foam

These include all types of light foam as well as memory foam. To be considered low-density foam, the material in this category must weigh less than 20 kg. But those that weigh from 20 to 24 kgs are classified as medium density whereas that above 24kg are termed as high-density foam. There is no limit to using either low or medium density foam materials with the CNC router. In fact, you may use any speed you want on these materials as long as you feel comfortable with it.

2) High-density foam

High-density foam materials are also referred to as ultra-high hardness packaging foams. In that respect, the hardness of the foam materials refers to how firm it is, and it is measurable by taking a standard piece of foam material and then record the amount of pressure needed to compress it. To make it clearer, hardness and density should not confuse you. High-density foam does not necessarily mean that the foam material is hard while low density does not translate to mean soft as far as these materials are concerned.

Plastic

1) Soft plastic

This refers to the polyethylene soft plastic materials. The good thing with the soft plastic is that it bends easily and it is somehow flexible. Also, when dropped, it can withstand the impact as well as make a muted thump like sound. The best examples of such materials include ABS, Polycarbonate, PVC and many more.

2) Hard plastic

Hard plastics refer to the polystyrene brittle plastic materials. One of the examples of the hard plastic materials is the plastic for the model kit. This material breaks easily when you bend them, and when dropped onto a hard surface, they make a “click “or the “tink” sounds.

Acrylic

They come in both colored and the colorless cast acrylic materials. They are normally branded as Perspex plastics, Plexiglas, acrylic glass and many others. These materials stand strong when using a CNC router on them. They are beautiful, versatile as well as durable and they come in different sizes and thickness that are easy to fabricate. To add on that, special router bits designed for plastic give a good finish and polish on acrylic materials, especially at the edges.

Looking for a router table? Check out our review.

Soft metal

These are aluminum, copper, bronze, mild steel and gold (24 carats). Aluminum is commonly used because it is readily available and durable. Aluminum is able to withstand any form of weather condition, and it is absolutely recyclable. For these metal materials, there are special CNC router bits that make a smooth and easy cut on them.

High-Pressure Laminate (HPL)

These materials are highly durable and easy to decorate when working on them using a CNC router. Examples are laminate floors, Formica and many more.

Phonic

Examples include:

● Phenol formaldehyde resin

● Phenolic panels

● Phenolic boards

● Maritex Aquarius

● Bakelite

● Tufnol plates

Conclusion

From the materials mentioned above, it is clear that a CNC router gives a chance to work on different materials. As long as the right router bit is put in place, the results will be quite fulfilling.