A Guide on Biscuit Joinery in Details

Wood working joinery is an important component of any project. Many types of joints exist and each one has its pros and cons. However, biscuit joinery in wood working is very popular and many wood workers apply in most of their projects. A biscuit joint is popular since it can be used in any type of wood and wood combination. It has a thin and oval shape and is made up of compressed wood shavings that look like a biscuit and that may explain where the name comes from.

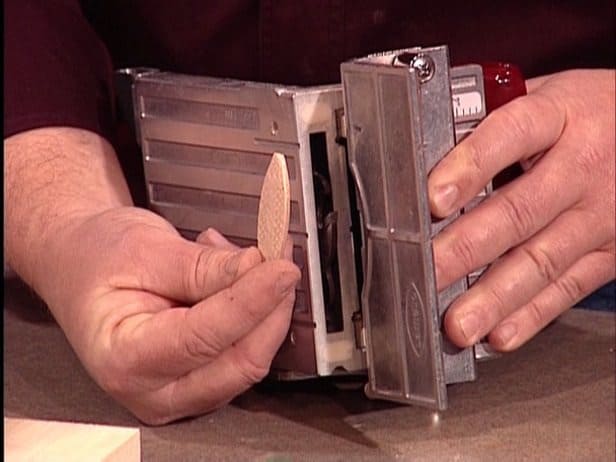

The biscuit joiner is used is one of the tools that can be used to make this joint. You can also use a wood router to make a biscuit since it is a versatile tool with an ability to handle any project. In this guide on biscuit joinery in details, we shall cover all you need about biscuit joinery.

What about Biscuit Joinery? When is it used?

Biscuit joinery is a highly debated topic. Many comments such as “never use this joint since it adds no strength”, “they are great for most applications” just to name a few, exist online. All these are confusing and it makes you wonder whether this is a joint that is worth adding to your piece of work. However, according to professional wood workers, a biscuit joint is useful depending on how it is used.

The effectiveness of a biscuit joint depends on the project in question. For instance, if your joint will be subjected to heavy pressure such as leg/stretcher joint, you will need heavier duty joinery. For small projects such as small boxes, cabinet carcases, accent tables and others, a biscuit will suffice. You can also use biscuit joinery from time to time on some high-stress joints but ensure you add in some reinforcement.

Types of Edges where Biscuit Joint is Used

Ideally, five types of joints use biscuit joints, namely:

- Edge to Edge joints: This type of joint involves joining the edges of two boards to form a disk shaped wood.U used in this type of joint aligns the surface between the two pieces of wood.

- Mitre Joints: A mitre joint is normally used to hide the end grain of a board. They are used in picture frames, round opening, and in window and door trims. The biscuit joint is used to reinforce this joint.

- Corner joints: The corner joint is normally designed for welding 12 gauge or thinner metals. The biscuit joint that perfectly fits between the joints is selected.

- T-Joints: These T-shaped joints make use of biscuit joints. The biscuit that fits excellently between the slots is inserted.

- Butt Joint: This joint provides the desired strength when you are welding metals with more than 3/16 inch thickness. The biscuit is used to reinforce this joint.

The Best Tool for Biscuit Joinery

The biscuit joiner is the most popular tool used in making biscuit joints. It is also used other applications such as making cupboard, furniture, drawers, and many others. This tool is a great asset when it comes to joining sheets such as plywood, medium-density fibre board, and particle board. Besides this tool, a wood router is also an exceptional tool used when making biscuit joinery. It is highly versatile and powerful.

The use of the Wood Router for Biscuit Joinery

A medium-sized handheld router with at least ½ inch collet and a slot-cutter router bit of preferably 5/32 inch thickness is ideal for making a biscuit joint.

The Pros of using the Router for Biscuit Joint

- Ideal for those who do not have a biscuit joiner and cut 30 or less biscuit grooves every year.

- Delivers exceptional accuracy for flush alignment two pieces of work.

- Those who own the router already only need to buy a $40 biscuit joint router bit set.

- The body of the biscuit joiner makes it hard to reach some tight corners and the wood router easily reaches these areas.

The Cons

- The router is slower when compared to a biscuit joiner.

- Routed grooves are not consistent as those cut by a biscuit joiner.

Size of Biscuit Joints

There are generally three options when it comes to the size of biscuit joints. These include:

- #0, equivalent to 5/8 Inch width X 1-3/4 inch length.

- #10, e4quivalent to ¾ inch width X 2-1/8″ length.

- #20, equivalent to 1 inch width X 2-3/8 inch length.

You should choose an ideal size of the biscuit depending on your project. Try in most cases to use the larger biscuit size that is a perfect fit for the project at hand, preferably #20. For your thin frames use the #10 biscuit size or alternatively #0 biscuits.

Procedure of Making Biscuits Joints

To rout out your grooves you need to mark the centre mark, routing start and the stop mark. Have the layouts for the biscuits at hand then attach the slot-cutter bit into the router and adjust the bit height. Secure the workpiece on the router table or workbench. Align the router sub base with the workpiece and plunge in the slot-cutter bit such that the bit shank is centred at the start mark. Align the bit shank with the end mark by moving the router right until this is achieved. You can then pull the slot-cutter from the groove. A clear sub-base makes this process so much easier.

For the #20 setup use 1-7/8 inch dia slot cutter with a bearing of 7/8 inch. Identify and mark the center line then mark the start and stop mark on each side of the centerline 7/16 inch away. This will cut a 2-1/2 inch in length by ½ inch deep groove.

For the #10 groove setup, use 1-7/8 inch dia slot-cutter with a bearing of 1-1/8 inches. Identify and mark your center line then mark the start and stop mark at 3/8 iches radius from the centerline. The resulting groove from the cut will measure 2-1/4 inch in length by 3/8 inches deepness.

For the #0 setup, make use of the 1-7/8 inch dia slot cutter with a bearing of 1-1/4 bearing. Put a mark at the centerline and mark the start and stop marks within a radius of 5/16 inches on the side of the centerline. The resultant groove will be 2 inches long by 5/16 deep.

Conclusion

Biscuit joinery is essential for most wood working projects. These joints are quite easy to “rout out” and will help reinforce your workpieces. Practice often using them and with time you will realise it is hard to do without them.